Grinding Agent

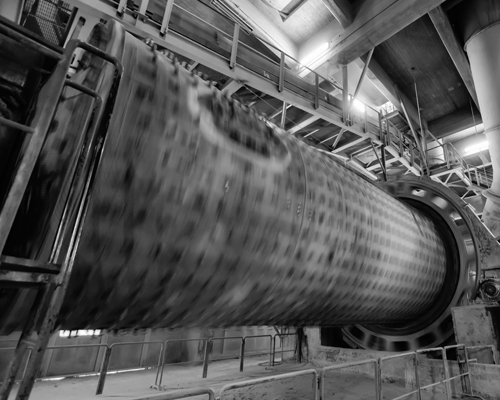

Grinding agent is a Key component for cement plants. They are generally chemical compounds that are used in the production of cement, with the objective of minimizing manufacturing costs, and maximizing value for the user.

Cement plants are expected to deliver superior performance while reducing production costs and lessening their environmental footprint. Our grinding agents make it easy to achieve these goals, by:

- increasing manufacturing capacity;

- reducing energy consumption;

Grinders and grinding agents can be used in concrete, mortar, and grout. Cement and aggregates are combined with water to form concrete, but also with various chemical additives that can modify its properties. These additives are called “grinding aids” because they improve the mechanical properties of the mixture.

Grinding aid or grinding additives refer to substances which when mixed into the mill contents cause an increase in rate of size reduction [1]. These terms are very common in cement industries where it is used to increase the throughput to the mill. Grinding aid also affect the cement flowabilitiy throughout the circuits. The grinding aid facilitates size reduction so that the mill has to apply less grinding power without having adverse effect on any of the properties of the resulting cement. Another beneficial effect of grinding aids used today is to decrease compaction in storage. It is generally improves grinding efficiency, by bringing down the limit of grinding.

F.A.Q

HOW DO GRINDING AGENTS WORK?

The most important impact of grinding agent, is to reduce the effects of the attraction forces between particles. Fine particles are better dispersed and more easily separated in end product. This allows advantages on grinding efficiency via:

– Reduction of the agglomeration and the “coating” of the grinding elements.

– Improved product dispersion from feed to separator, increased separator efficiency, reduced by-pass

– Reduction of crusher fill level.

– Cannonballs spend more time grinding coarse material

DEFINITION OF A GRINDING AGENT

Grinding agent are products used to improve grinding by preventing the agglomeration of particles, by neutralizing electrostatic charges.

The grinding agent is added to the powdered material to improve its flowability before processing. They significantly reduce friction and segregation, which helps increase yield, improve product quality and reduce production costs.

Have you a grinding agent need for your cement factory ?

Our teams are at your disposal. Just contact us:

Tel: +216 71 752 300

Email: sales@tunisia-building-partners.com

Grinding agent is a substance that is added to cement to improve its quality, making it easier to mix and more durable. Grinding agents are used in a number of applications, including road construction and concrete production.

Cement manufacturers use grinding agents to improve the strength of their products. They do this by increasing the density of the final product by adding small amounts of sand or other materials. The exact amount of material used depends on the type of cement being produced and whether it is intended for industrial or residential use.

Grinding agent for cement factory is the most important raw material for grinding the cement. The main functions of the grinding agent are:

1) High hardness, wear resistance, excellent wear resistance and corrosion resistance.

2) Good adhesion to the surface, long service life and easy to clean.

3) It is easy to mix with other materials.